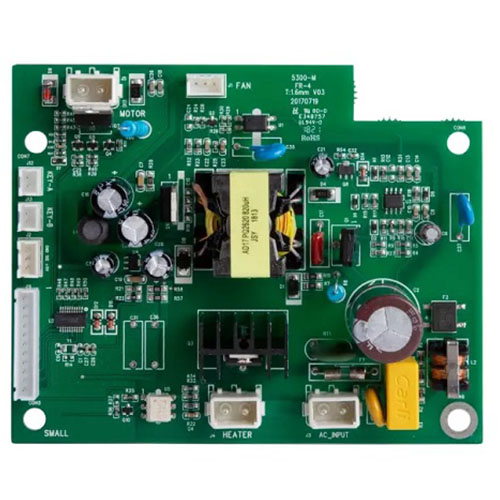

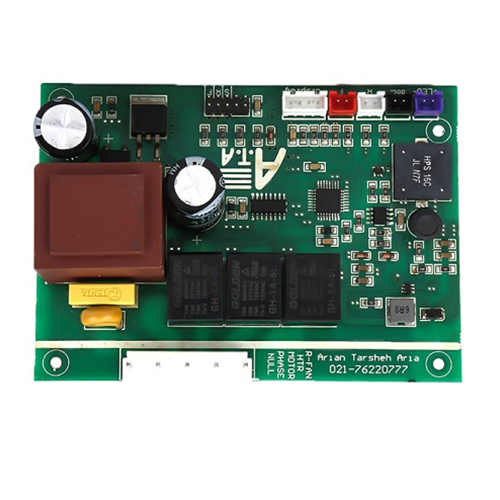

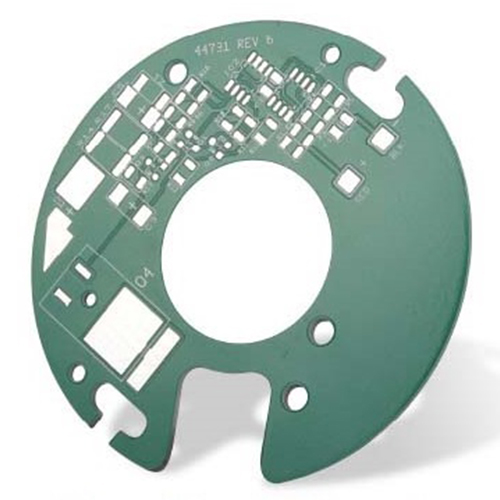

2-layer aluminum PCB is a kind of high performance circuit board. It uses aluminum base material as the substrate, has excellent heat dissipation performance and mechanical strength, widely used in LED lighting, power supply, automotive electronics, communication equipment and other fields.

1. Manufacturing process

The manufacturing process of 2-layer aluminum PCB is different from that of ordinary FR4 PCB, mainly including the following steps:

1. Substrate preparation: aluminum base material is processed by cutting, polishing, cleaning and other processes to make the substrate meet the requirements.

2. Printed circuit pattern: the circuit pattern is transferred to the aluminum substrate through lithography technology to form a conductive pattern.

3. Chemical etching: etching away the aluminum material that does not cover the circuit pattern to form a conductive path.

4. Gold plating layer: a layer of metal is plated on the conductive pattern to improve electrical conductivity and corrosion resistance.

5. Welding components: The electronic components are fixed on the aluminum substrate through welding technology.

6. Testing and packaging: Electrical performance testing and appearance inspection of aluminum PCB are carried out before packaging.

2. Characteristics

The 2-layer aluminum PCB has the following characteristics:

1. Excellent heat dissipation performance: aluminum base material has good thermal conductivity, can effectively transfer the heat on the circuit board to the external environment, so as to ensure the stability and reliability of the circuit board.

2. High strength and rigidity: aluminum base material has high strength and rigidity, can withstand greater mechanical stress and vibration, so as to ensure the stability and reliability of the circuit board.

3. Good corrosion resistance: aluminum based materials have good corrosion resistance and can run stably in harsh environment for a long time.

4. Suitable for high power applications: Aluminum PCB can withstand high power density, suitable for high power applications, such as LED lighting, power supply, automotive electronics, etc.

5. Can achieve a variety of surface treatment: aluminum PCB can achieve a variety of surface treatment, such as spraying, anodic oxidation, electroless nickel plating, to meet the needs of different application fields.

3. Application

2-layer aluminum PCB is widely used in the following fields:

1. LED lighting: Aluminum PCB can effectively heat dissipation, suitable for high-power LED lighting products.

2. Power supply: Aluminum PCB can withstand high power density, suitable for high power supply products.

3. Automotive electronics: Aluminum PCB has high strength and rigidity, can withstand automotive vibration and impact, suitable for automotive electronics.

4. Communication equipment: Aluminum PCB has good corrosion resistance, suitable for communication equipment products.

In short, 2-layer aluminum PCB is a kind of high-performance circuit board, with excellent heat dissipation performance, high strength and rigidity, good corrosion resistance and other characteristics, widely used in LED lighting, power supplies, automotive electronics, communication equipment and other fields.

English

English  Esperanto

Esperanto  Afrikaans

Afrikaans  עִברִית

עִברִית  Galego

Galego  icelandic

icelandic  Беларус

Беларус  Hrvatski

Hrvatski  Shqiptar

Shqiptar  Malti

Malti  Bosanski

Bosanski  Frysk

Frysk  Samoa

Samoa  Gàidhlig

Gàidhlig  O'zbek

O'zbek  հայերեն

հայերեն  Lëtzebuergesch

Lëtzebuergesch  Español

Español  Português

Português  русский

русский  français

français  日本語

日本語  Deutsch

Deutsch  Tiếng Việt

Tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ไทย

ไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  Malay

Malay  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Türk

Türk  Gaeilge

Gaeilge  norsk

norsk  čeština

čeština  Ελληνικά

Ελληνικά  Українська

Українська  فارسی

فارسی  Burmese

Burmese  български

български  Latine

Latine  slovenský

slovenský  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  Српски

Српски